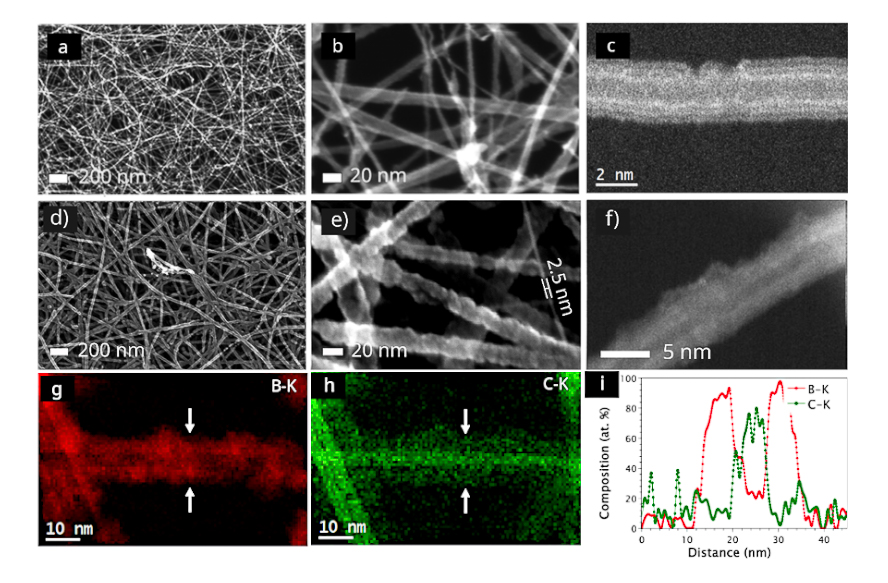

a-b) SEM micrographs showing a pristine CNT membrane. c) ADF STEM image of a single CNT. d)-e) SEM images showing uniform deposition of a thin film on the CNT membrane. f) ADF STEM image showing a CNT after CVD. g) EELS B-K map. h) EELS C-K map. i) EELS line scans across the B4C deposited CNT indicated by white arrows.

B4C coated carbon nanotubes via chemical vapor deposition

Historically, single-walled carbon nanotubes (CNTs) are considered strong candidates for water treatment, desalination, chemical separation, and energy storage applications. However, they are susceptible to degradation in harsh environments. Protective coatings on CNTs is therefore an attractive solution. Previous reports on metal oxide coatings on CNT have shown to improve anti-fouling and anti-oxidation properties. Notably, it has been outstanding challenging to realize uniform coverage on CNTs, negatively affecting the protective capabilities. Recently, researchers at the Linköping University demonstrated conformal protective B4C coated CNTs via chemical vapor deposition (CVD). The researchers further demonstrated tuning potential by varying coating thickness and pore size as a function of growth parameters.

Linköping’s Titan3 scanning transmission electron microscope (STEM) is a suitable platform to perform experiments which requires high simultaneous spatial and energy resolution. Here annular dark field (ADF) STEM was employed together with electron energy-loss spectroscopy (EELS) to reveal chemical distribution of B and C in the single B4C coated CNTs.

Microscopy work was performed at LiU node of ARTEMI in collaboration with Arun Haridas Choolakkal and Henrik Pedersen from Linköping University.